Creating a dynamic and visually engaging online shopping experience requires precise tools, and 3D CAD files play a foundational role in this process. For companies implementing Dopple's 3D Product Configurator or Visualizer, gathering the appropriate CAD files is a critical first step.

This guide provides a comprehensive approach to:

By following the steps outlined, you enable Dopple’s 3D Team to review and optimize your CAD files for seamless integration, enhancing your eCommerce platform with cutting-edge 3D and augmented reality (AR) capabilities.

The transition to 3D commerce is reshaping how customers interact with products online. Dopple specializes in converting CAD assemblies into web-ready, runtime-optimized 3D models. These models form the backbone of interactive product configurators, enabling customers to visualize and customize products in real time.

To gather the necessary CAD assets, marketing teams must collaborate with engineering departments. The following roles typically manage or have access to the required files:

While marketing teams often focus on customer-facing activities, engineering teams prioritize product functionality and design. Providing context for why these files are needed ensures alignment.

Use the template below to initiate communication with your engineering team:

This email helps frame the collaboration as an exciting opportunity to elevate the company’s digital presence.

Begin by selecting a product that aligns with your eCommerce goals. Consider the following:

Begin by selecting a product that aligns with your eCommerce goals. Consider the following:

The top-level assembly includes all the major components of the product. Ensure this assembly captures the product’s essence while excluding unnecessary details to optimize performance. In many cases the CAD assets only come together in a physical format at the floor level. For Dopple projects we must get engineering alignment that we are looking for the digital top-level assembly for the purposes of putting the product together in 3D digital form.

If a Bill of Materials (BOM) is available, request it from engineering. Preferred formats include .xls or .csv. BOMs help Dopple understand the product’s structure, identifying which components to include in the 3D model.

Open the top-level assembly in SolidWorks.

Select File > Pack & Go.

Verify all files are selected; grayed-out files indicate missing components.

Check Include Toolbox Components.

Save the files to a designated folder.

For CAD engineers working in systems without native Pack & Go functionality:

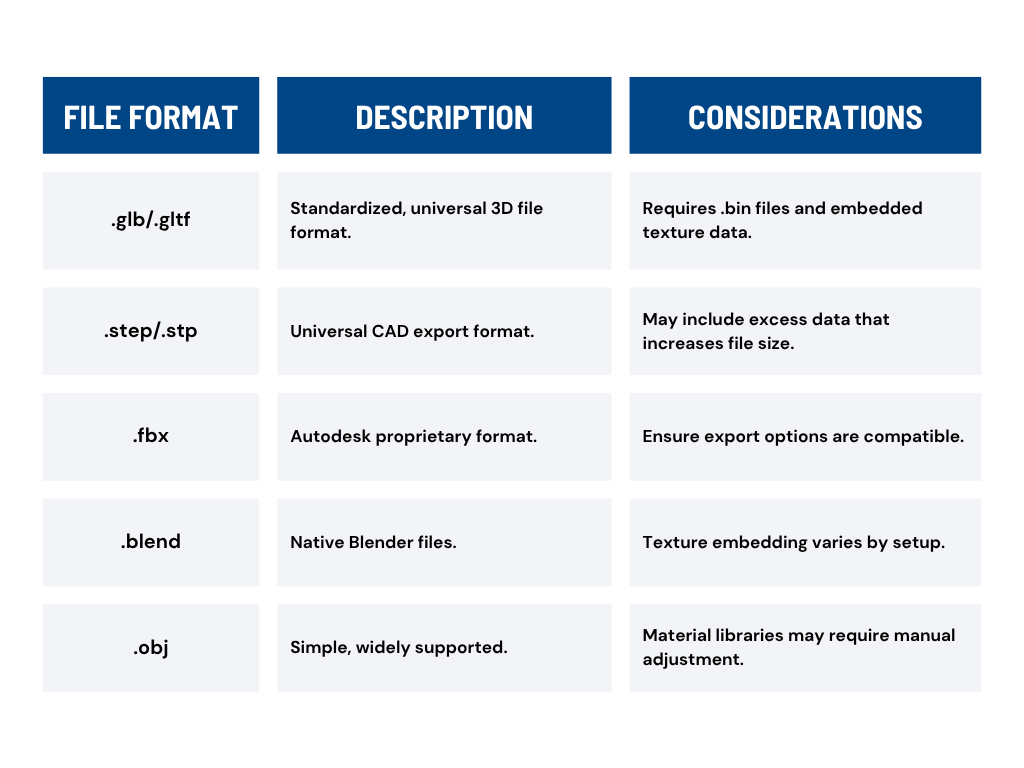

Dopple works with various file formats but has specific preferences for efficient processing:

CAD files often include unnecessary details that can slow down loading times or overwhelm online configurators. To address this:

Dopple’s Review Process

Once files are submitted, Dopple’s team will:

Start Small: Begin with one product to refine the process before scaling.

Communicate Clearly: Ensure all stakeholders understand the project goals and requirements.

Leverage Dopple’s Expertise: Engage with Dopple SMEs early to address any technical challenges.

Helpful Content:

FAQ Preparing and Delivering 3D CAD Files for Dopple

Common Challenges in Gathering 3D CAD Files and Implementing Dopple Projects